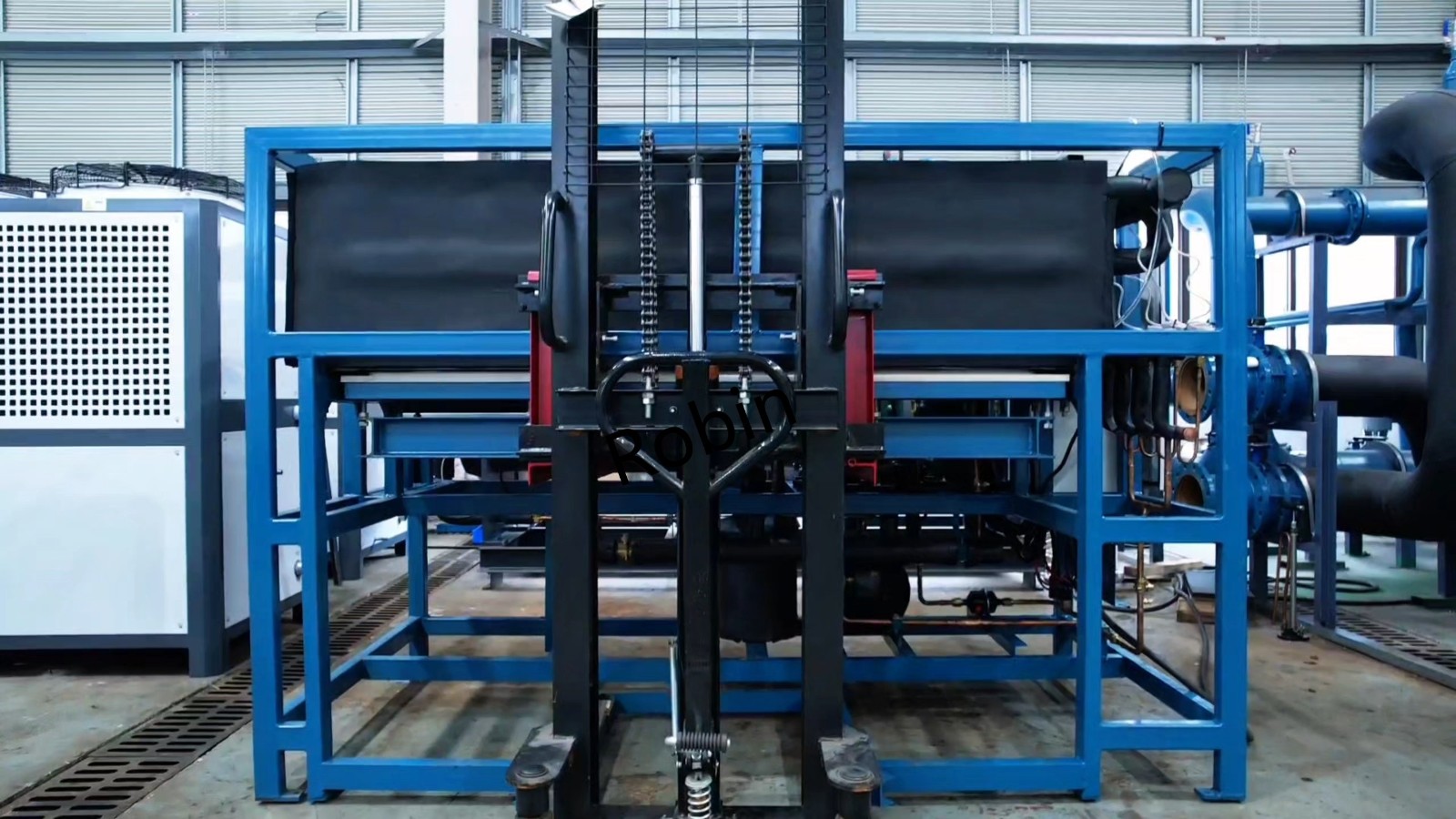

Customised 1-tonne Direct-Cooled Block Ice Machine for Congolese Client Completed

Recently, the company's bespoke 1-tonne direct-cooled block ice machine for a Congolese client has been fully manufactured and is poised for shipment to the customer's site. This equipment will support local ice supply requirements across cold chain logistics and food processing sectors. This direct-cooled block ice machine prioritises efficient ice production and stable operation. Featuring an air-cooled heat dissipation design and equipped with internationally renowned American Copeland compressors, it not only achieves refrigeration efficiency far exceeding standard equipment but also maintains continuous operation across varying ambient temperatures. This ensures the stability and longevity of the ice-making process, effectively reducing long-term operational and maintenance costs for the client.

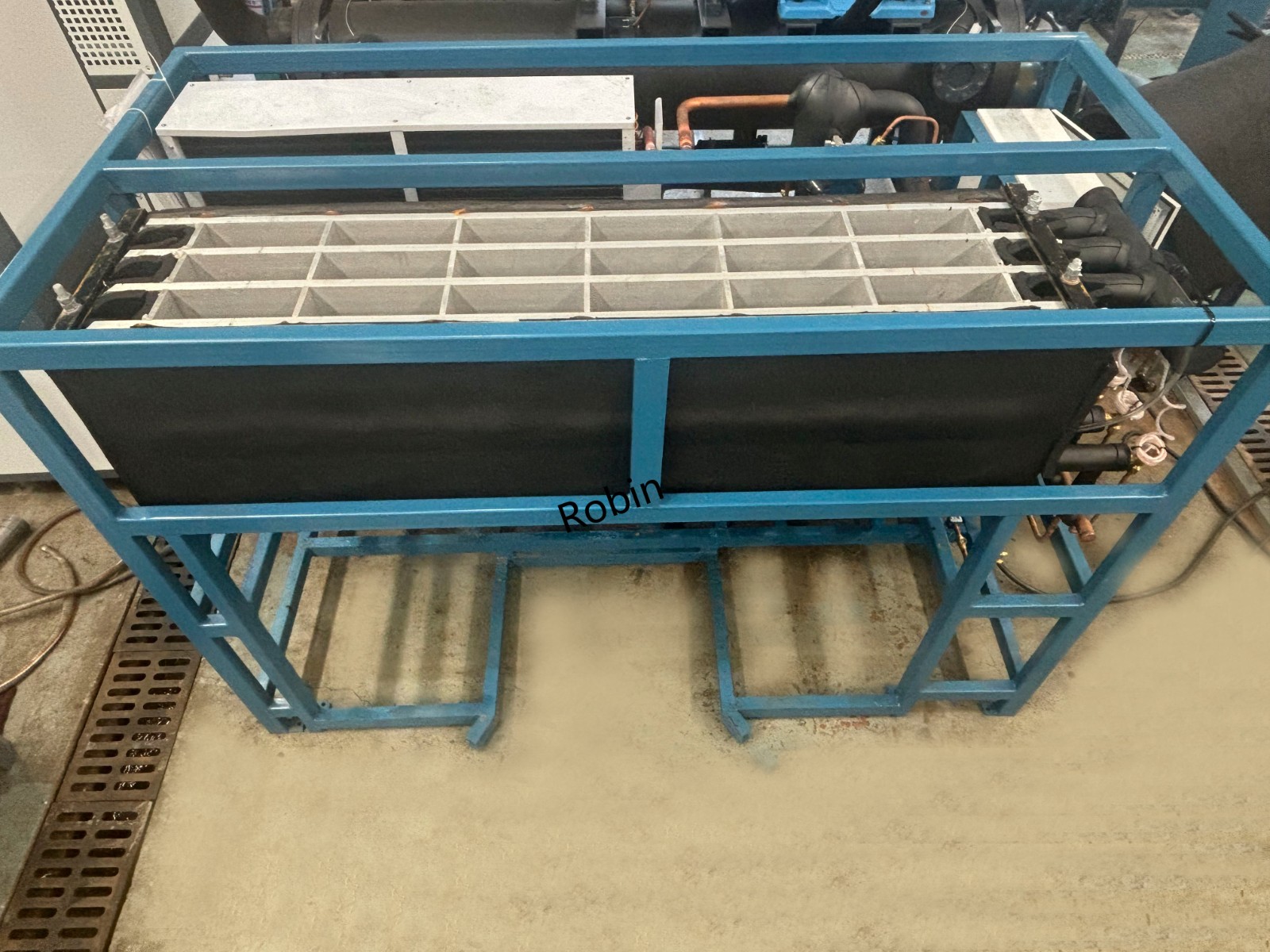

The machine's quality advantages are further highlighted in its core components and design. Its evaporator employs food-grade aluminium plates, meeting food contact safety standards to ensure pure, contamination-free ice while offering exceptional corrosion resistance. This effectively withstands long-term exposure to moisture and frost during continuous operation, extending the unit's lifespan. Furthermore, aluminium's thermal conductivity—second only to silver, copper, and gold—enables highly efficient heat transfer, significantly shortening the ice-making cycle and boosting hourly ice output.

Notably, the evaporator employs advanced plug-in technology instead of traditional welding, fundamentally eliminating issues of oxidation and leakage at weld points while ensuring stable, distortion-resistant aluminium plate structure. This weld-free design also guarantees smooth ice release, effectively preventing incomplete extraction or ice block fragmentation caused by weld-point jamming.

Furthermore, the unit incorporates a Siemens PLC control panel, enabling fully automated integrated operation for water filling, ice production, and ice discharge. The entire ice-making process is completed with a single button press.